Walking down the aisle of a hardware supplier or browsing online for diamond blades can be overwhelming. With countless rim designs, sizes, and specifications, picking the wrong blade is all too easy—and the cost of that mistake is often a cracked slab of expensive Italian marble or a jagged edge on a porcelain tile.

Choosing the right blade isn't just about fitting it onto your angle grinder; it’s about matching the engineering of the blade to the physics of the material. Here is your professional guide to selecting the perfect tool for your next stonework project.

The most critical factor is the "rim" or the cutting edge. Different designs are engineered for different interactions with stone.

Using the wrong size blade on your grinder is not only inefficient but dangerous. The size of the blade determines the depth of your cut and the surface speed of the diamond segments.

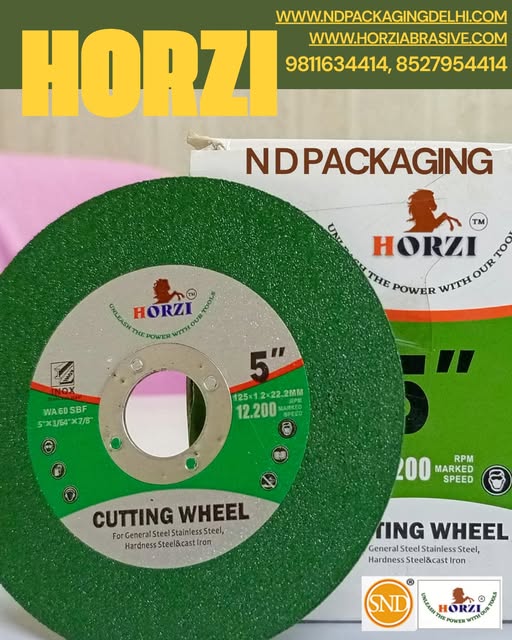

Horzi Abrasive specializes in the three most essential industry sizes:

The "right" blade is simply the one that balances speed, finish quality, and lifespan for your specific material. Don't gamble with your finish—invest in blades engineered with high-quality diamond powder and hot press technology.

Equip Your Team with Horzi Abrasive

Ensure your next cut is your best cut. Contact us for premium diamond tools tailored for professional stoneworkers.

|

Detail |

Information |

|---|---|

|

Phone (Deepak Gupta) |

+91-9811634414 |

|

|

information@horziabrasive.com |

|

Website |

|

|

Address |

Khasra No 52/18, Vil Prahaldpur Bangar, Nr Karat Godown, Delhi-110042 (India) |