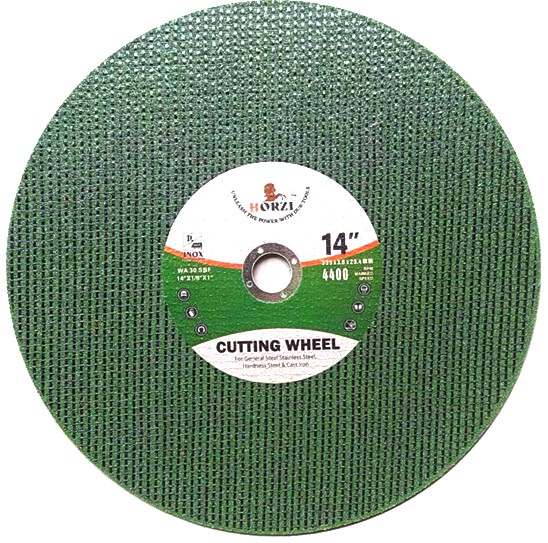

In metal fabrication and industrial cutting operations, speed and precision play a crucial role in productivity and overall output quality. Fast Cutting Super Thin Cut Off Wheels are specially developed to meet these demands by offering smooth, quick, and accurate cutting performance across a wide range of metals.

These wheels feature an ultra-thin design that minimizes cutting resistance, allowing faster material penetration with less effort. As a result, operators can complete cutting tasks efficiently while maintaining consistent accuracy and clean edges.

High-Speed Cutting Performance

Fast cutting super thin cut off wheels are designed to deliver rapid cutting action without excessive pressure. Their thin structure allows the wheel to move smoothly through metal, reducing cutting time and increasing work efficiency, especially in high-volume production environments.

Low Heat Generation and Material Safety

Due to reduced friction, these wheels generate less heat during cutting, which helps prevent metal burning, discoloration, or deformation. This ensures the integrity of the material is maintained, making them suitable for stainless steel and heat-sensitive metals.

Clean and Accurate Cutting Results

Super thin cut off wheels produce straight, narrow cuts with minimal burr formation. This results in a clean finish and reduces the need for secondary grinding or finishing, saving both time and labor costs.

Improved Productivity and Cost Efficiency

Faster cutting speed, reduced material loss, and lower rework requirements make these wheels highly cost-effective. They help improve overall productivity while minimizing operational expenses in fabrication workshops.

Wide Range of Metal Applications

Fast cutting super thin cut off wheels are suitable for cutting mild steel, stainless steel, aluminum, and other non-ferrous metals, making them a versatile choice for various industrial applications.

Conclusion

Fast Cutting Super Thin Cut Off Wheels are an essential solution for modern metal fabrication, offering speed, precision, clean finish, and efficiency.

With Horzi Abrasive, these wheels are engineered to deliver reliable, long-lasting performance that meets professional industrial standards.